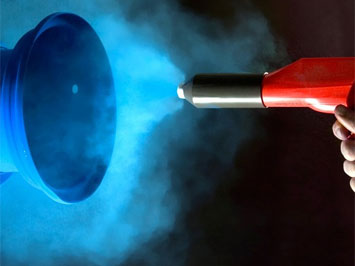

Application of polifluid process

What is Polifluid?

A new powder coating method that allows working with a cold ionized carrier enriched in nitrogen at lower pressures and at a constant temperature (10°C). It has significant advantages in terms of saving, productivity, quality and environmental friendliness.

Polifluid principle of operation

During the powder coating process in Polifluid technology compressed air is replaced with enriched nitrogen (90-92%) both in spray guns and in a liquefied bed.

In the synthesis, the powdered product was optimized with a new high density carrier.

The carrier is a part of a mixture of gases represented in the compressed air but have a different molecular fraction.

In addition, this new carrier is cooled and kept under control at a constant temperature (10°C) regardless of environmental conditions.

All this helps to avoid major inconveniences in the powder coating process and to obtain significant advantages.

Why is the carrier enriched with nitrogen?

Nitrogen is a chemical element with atomic number 7. Molecular nitrogen is a colourless inert gas, odourless and tasteless, accounting for 78% of the Earth atmosphere (it has the highest percentage in atmospheric air).

Nitrogen is anhydrous and inert gas without impurities (like dust, oil, vapours, chemical pollutants and moisture). Due to these properties, colouring with a carrier enriched with nitrogen makes it possible to obtain smaller particles of the powder (there is no aggregation due to humidity).

Powder particles with nitrogen as a carrier are faster (13 m / s) than ones with compressed air (7 m / s). In this regard you can use the same amount of powder but at lower pressures.

Are you interested?

Fill in a questionnaire and get a discount

Are you interested?

Fill in a questionnaire and get a discount

of 5 to 10%!

The advantages of using

Easy to use and reduce the application time

Easy to use and reduce the application time

As a result of our tests, our clients obtained positive results. They drew attention to the insignificant time required to apply the powder and fewer repeated actions at that.

Best distribution of powder coating

Best distribution of powder coating

The frame effect is reduced. The coating has a better distribution over the part surface. Differences in the layer thickness are reduced to 80%.

Decrease in the effect of Faraday cage

Decrease in the effect of Faraday cage

By applying Polifluid the powder better covers hard-to-reach areas (internal corners, deeply located parts etc.). After drying, it is easy to visualize a uniform and complete coating of parts even in shadow areas.

Reduction of excessive spraying (overspray) in a paint chamber

Reduction of excessive spraying (overspray) in a paint chamber

The Polifluid system allows spraying the powder more evenly, up to 70%. The consequence of this is a reduction in excessive over-spraying.

Productivity increase

Productivity increase

The ease of application results in the possibility of increasing the line speed. In addition, quality improvement leads to less waste.

Reduced maintenance

Reduced maintenance

Maintenance of wearing parts to be replaced is also reduced. For example, nozzles can serve twice as long.

Installation

The Polifluid system is suitable for any type of powder painting line / equipment.

The device is selected according to the performance depending on the parameters of the already installed equipment for powder coating (volume of consumed carrier).