Application of nitrothermspray process

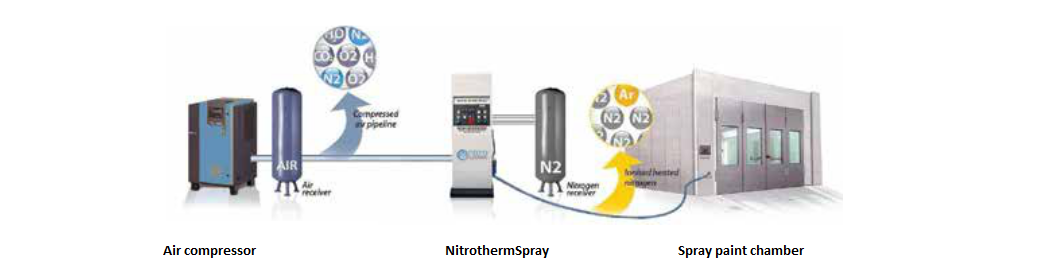

Automotive industry and car repair service

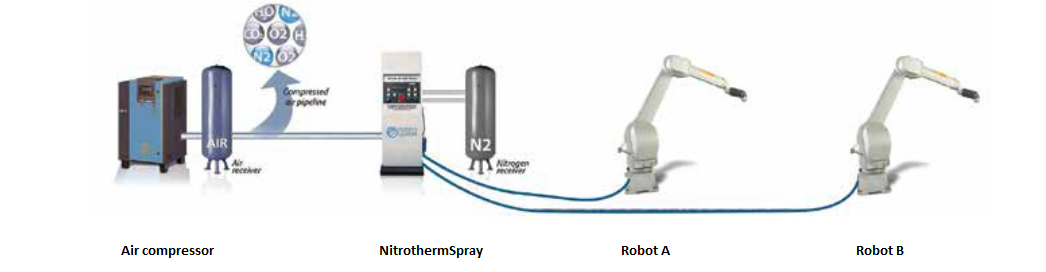

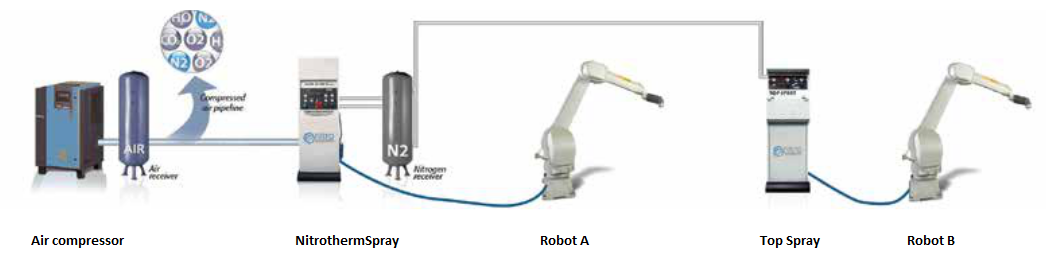

Nitrothermspray technology has been used successfully in the automotive industry ranging from large automakers using robotic paint lines; medium-sized industries that paint lights, panels, bumpers etc. manually or with the help of automation; up to small companies that manually paint small parts.

Car repair shops were the first customers for Nitrothermspray. Today, more than 400 medium-sized car repair shops use our system. All the customers confirm that with Nitrothermspray they can achieve a cleaner and more accurate painting, reduce the time of painting and drying, and achieve paint savings of up to 40%.

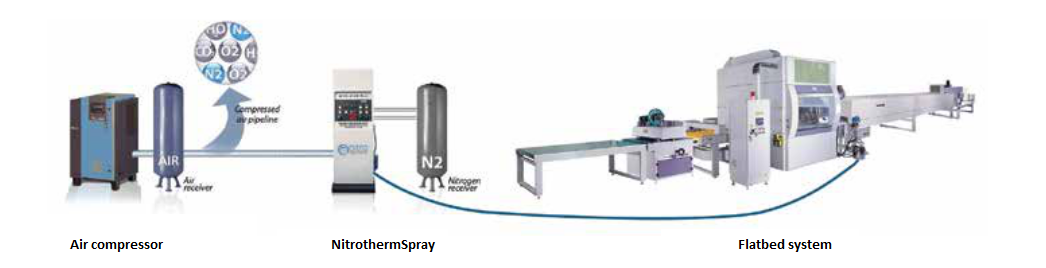

Woodworking industry and metal working

Nitrogen is an inert anhydrous gas (the condensation point is below -40 °C), which makes it an excellent instrument for application in the field of painting wooden surfaces.

When using a Nitrothermspray, the percentage of microbubbles formed between the coating and the surface to be painted is halved, which makes it an ideal instrument for applying also glue.

Our technology is suitable for all applications in the field of metal working and painting. We have installed Nitrothermspray in a variety of industries, starting with small ones, which paint small products, and ending with enterprises that paint railroad cars, trucks and aircraft.

Are you interested?

Fill in a questionnaire and get a discount

Are you interested?

Fill in a questionnaire and get a discount

of 5 to 10%!

Process

In the Nitrothermspray system, the traditional carrier of paint mixture, which is purified compressed air, is replaced with nitrogen (up to 97.5%) so that the paint mixture remains clean, dry and free from contaminants.

The result is reduced overspray losses and up to 30% paint savings.

Another advantage of using nitrogen as a carrier is that it reduces the diameter of the paint drop and the ratio of the volume of the paint to the coating area, provides a faster evaporation from the surface and a better spreading rate / distribution of the applied paint during spraying.

In addition, when nitrogen is heated, the viscosity of paint decreases and consequently the need to use solvents is reduced (up to 50%).

With the NitrothermSpray equipment, all types of paints, air compressors, spray guns can be used. The equipment can be easily installed on all types of existing paint systems and used in all environmental conditions.

Installation